New recirculation pump installed at Olkiluoto power plant

TVO continues projects related to the lifespan management of the operating plant units by a replacement project of the original recirculation pumps at both plant units during the annual outages of 2016–2018.

The replacement of the pumps is one of the most important modernisation projects ever carried out in the history of TVO. The first pump was replaced this year at the Olkiluoto 1 plant unit.

There are six recirculation pumps at both plant units and they are all going to be replaced. Two reserve pumps will also be installed at each unit. The replacement project also includes the modernisation of the frequency converters used e.g. for the RPM (revolutions per minute) control of the pumps.

– There have not been many similar replacement projects even on the global scale. The project actually started already in 2008, and a massive amount of pre-engineering and product development work as well as preparatory work for licensing has been carried out since. This project has meant a lot of extra work for quality control and licensing, explains Seppo Keränen who works as an engineer in Power Plant Engineering at TVO.

The replacement project is carried out by Westinghouse Electric Sweden (WSE) in cooperation with TVO. The pumps are manufactured by the German company KSB Aktiengesellschaft. The total project value is more than EUR 40 million.

One of the most important main components

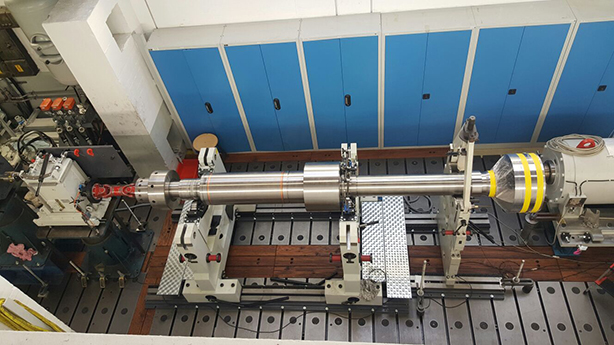

The recirculation pumps are installed with even spacing on the bottom of the reactor pressure vessel. They circulate water through the reactor core, and produce a flow that at a maximum rate of 10,000 kg/s is higher than was possible to achieve with the old pumps. The electrical output of the new pump motor is 1,000 kW and the combined weight of the pump and the motor is 5,270 kg.

– The decision on the replacement was made, because the pumps are more than 35 years old and the availability of product support and spare parts from the original equipment manufacturer has been significantly reduced.

The new pumps are in the main parts similar to the old pumps. The most important difference is the flywheel mounted on the pump shaft to ensure the safe shutdown of the recirculation pumps in case power supply is lost. This also makes the licensing of the frequency converters easier.

- The pumps were tested in many test procedures before installation at the plant unit, and numerous analyses were made on the pumps. As required by good safety culture, we will now verify how everything works in practice before replacing the other pumps, says Mr. Keränen.

Extreme precision required in replacement process

The replacement was carried out during the annual outage and in most parts everything went by the book. The changes that were required were quickly reacted to.

- The replacement of such a large component is not a minor operation. For example, special tools were needed that could not be purchased from a normal tool store. In most cases, the tools delivered for the original pumps were not suitable either, explains Mr. Keränen.

The other recirculation pumps will be replaced during the upcoming annual outages. All six pumps at OL2 are to be replaced in 2017, and the remaining pumps of OL1 in 2018.

- The first replacement provided valuable experience that will be utilised in the next replacement processes. We are now analysing the things that could be done even better next time, concludes Mr. Keränen.

The shaft of the recirculation pump is about four metres in length. (Picture: Seppo Keränen's archive)

Share