Reactor safety

During operation, a nuclear reactor will accumulate a large amount of radioactive substances. These substances must be efficiently isolated from the environment.

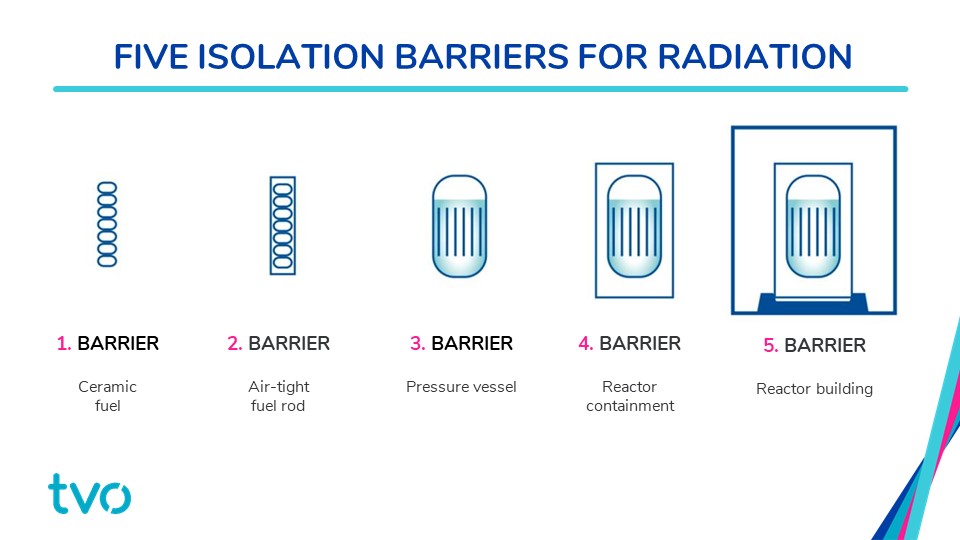

Various release barriers are used for the purpose of this isolation. The first release barrier is the ceramic fuel that efficiently retains the fission products located therein. The second barrier is the fuel cladding. The third release barrier is the reactor pressure vessel that contains the reactor core. The fourth barrier is the gas-tight containment that surrounds the entire reactor system, and the fifth barrier is the reactor building that houses the entire containment.

The radiation energy inside the radioactive substances that accumulate in the fuel will continue to generate heat even after the reactor has been shut down. This is known as residual heat, and it will initially amount to a few per cent of the reactor’s thermal output but will then decrease slowly.

Aiming to control the chain reaction and residual heat

The starting point for reactor safety is that the uranium fission chain reaction and the power it generates are always under control and that the removal of the residual heat caused by the radioactivity in the fuel can be ensured under all conditions.

A nuclear power plant is equipped with multiple safety systems that can quickly detect and control any operational occurrences. If necessary, an automatic scram will stop the reactor by driving the control rods inside the reactor core within a few seconds.

Residual heat removal is started with an emergency cooling system that supplies water into the reactor at high pressure. As reactor pressure drops, emergency cooling is shifted to the core spray system. Both systems and their related auxiliary systems are divided into mutually independent subsystems in order to ensure safety in case of component failure.

Picture: The reactor pool of OL2