Olkiluoto 3 fuel thoroughly checked during ongoing annual outage

Fuel Handling Manager Vesa Leskinen, who has worked at TVO for 34 years, enjoys the challenging nature of his job. And challenges are many also during the ongoing, first ever annual outage at OL3. The fuel in use at the new plant is subjected to a close scrutiny now, because the entire reactor core of OL3 will be unloaded for various imaging tasks and measurements.

The energy production of a nuclear power plant is based on a controlled chain reaction occurring in the uranium fuel. According to Leskinen, the fundamental principles of nuclear power have remained unchanged, but the technology used at the plants has changed over the three decades.

- The technology has undergone digitalisation and the output of the turbines has increased. Furthermore, fuel manufacturers develop their products all the time to increase the amount of energy obtainable with the same amount of fuel.

Part of the fuel is replaced at nuclear power plants in connection with annual outages. At OL3, for example, 76 new fuel elements will be loaded in the reactor during the outage. According to Leskinen, because annual outages involve the handling of nuclear fuel with a high level of radioactivity, diligent planning, special equipment, and strong professional competence are required for the work.

Round-the-clock work for 20 days

- Compared with the OL1 and OL2 plant units, the fuel handling process is different during the annual outage of Olkiluoto 3. The first annual outage of OL3 includes a thorough inspection of the fuel. Nuclear fuel has never before been studied in as much detail as in this annual outage.

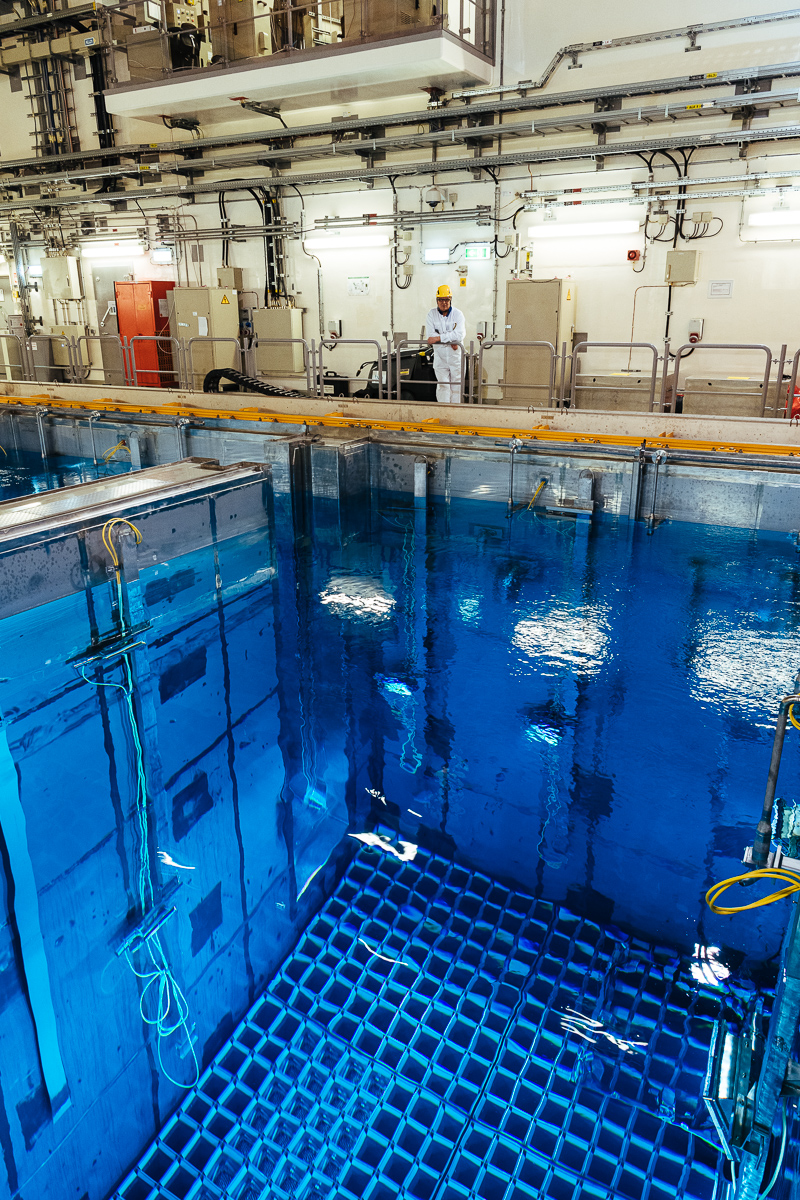

With a thorough inspection, Leskinen refers to the whole reactor core being completely unloaded at OL3. All fuel elements will undergo four-side imaging with high-resolution special imaging equipment. A bend measurement is carried out on all the elements and some of the elements will be subjected to oxide and length measurements. Visual inspections are performed also on the control rods and the thimble plug assemblies.

- The purpose of the inspections is to investigate the performance of the fuel type used at OL3 during test production and the first commercial production cycle. For TVO’s own employees and the foreign experts participating in the outage, this will mean round-the-clock work over a period of 20 days. All in all, 26 experts from outside the company are involved in the fuel inspections, and us as representatives of TVO must supervise all the work activities.

Leskinen does not mind the longer working days during the annual outage at all. Instead, he says he enjoys the challenges.

- The best thing about working at TVO is that every day is different and there are always new challenges to tackle. The work atmosphere is also good in Olkiluoto – it is easy to work here as one of a skilled team. And also, the precision of work in the nuclear industry is unique, which adds to the interesting nature of the work.

An old hand already

Vesa Leskinen, Fuel Handling Manager for Teollisuuden Voima, tells that it was 34 years ago this March that he started in the employ of TVO. And goes on to say that that is not all.

- After completing the senior secondary school, I took part in the annual outages of Olkiluoto 1 and 2 on many summers as an employee of a subcontractor. The Island of Olkiluoto became a familiar place already at that time.

Leskinen, who originally comes from Eurajoki, started in the employ of TVO in 1990. Before that, he had completed the degree of Bachelor of Mechanical Engineering and worked for about a year for Rauma-Repola. Since 1990, his nuclear knowledge has increased in many different positions: as a control room operator and in various fuel handling tasks.

- In 2021, I took on the responsibility of fuel handling activities at all the plant units. Apart from myself, the KPH Team consists of six fuel engineers who I try to keep under control, he chuckles.

To put it briefly, the fuel handling team is in charge of the entire life cycle of nuclear fuel “from cradle to grave”.

- We ensure that the uranium from the mines ends it journey, via the interim storage for spent fuel, in final disposal. The overall process includes many kinds of tasks, such as connections with the fuel manufacturer, control of manufacture, fuel transport arrangements, as well as reception and acceptance inspections of the fuel. Fuel inspections are carried out during both annual outages and the operating cycle, Leskinen explains.

I will be 62 years old this year. In a few years’ time, I will need to figure out how much longer I intend to work. At least at present I have no yearning for retirement, Vesa Leskinen concludes.

Uranium reaches Olkiluoto after many twists and turns

Uranium has undergone several processing phases before it is ready for use in a nuclear power plant. Rock and non-uranium minerals have been removed from the uranium ore which has been processed into raw uranium and enriched for use as fuel. Fuel manufacturers press uranium into fuel pellets which are loaded into fuel rods made from a zirconium alloy. The rods are then assembled into fuel elements according to the structural requirements of each reactor.

- Every year, some 200 fuel elements are brought to Olkiluoto for use at OL1 and OL2, and about 75 elements for OL3. The uranium contained in them weighs approximately 75 tons. In 2018, a large delivery arrived for the initial loading of OL3: 245 fuel elements with a total weight of about 200 tons, Leskinen tells.

TVO’s fuel elements come from Germany, Spain, and Sweden. The uranium they contain is mined in Canada, Australia, and Kazakhstan.

Text: Timo Sillanpää

Photos: Tapani Karjanlahti

Share