Annual outage on Finland’s most important generator is now complete

The annual outage for 2024 is now finished for the generator at Olkiluoto 3. This is good news for all of Finland because the most powerful nuclear power plant unit in Europe would not be able to deliver a single watt into the national grid without a working generator. This, in turn, would reduce Finland’s electricity generation capacity by 14 per cent.

The generator converts the kinetic energy of the turbine into electrical energy, which is generated by heating water with the thermal energy produced by nuclear reactions. As for other tasks, annual maintenance is still ongoing

-The actual maintenance work was completed on 1 April, and it was followed by the generator leak rate tests that are now also complete, says Taneli Sundell. He was in charge of leading the annual outage for the OL3 generator.

A hundred hours to cool

A total of approximately three weeks had been reserved for the maintenance and inspections at the generator. In addition to a long list of maintenance activities, this time was taken up by an especially large number of inspections and measurements. However, the teams first needed to wait a bit before work could be started.

- Prior to starting work, we had to wait for about one hundred hours for the turbine shaft to cool, Mr Sundell says. The wait was necessary, because stopping the shaft when it is too warm might even cause it to deform.

The headcount at the generator team, lead by Mr Sundell, was about 30.

- The maintenance team consisted of technicians and supervisors as well as inspectors and experts from various areas who analysed the findings of the numerous inspections, Mr Sundell explains.

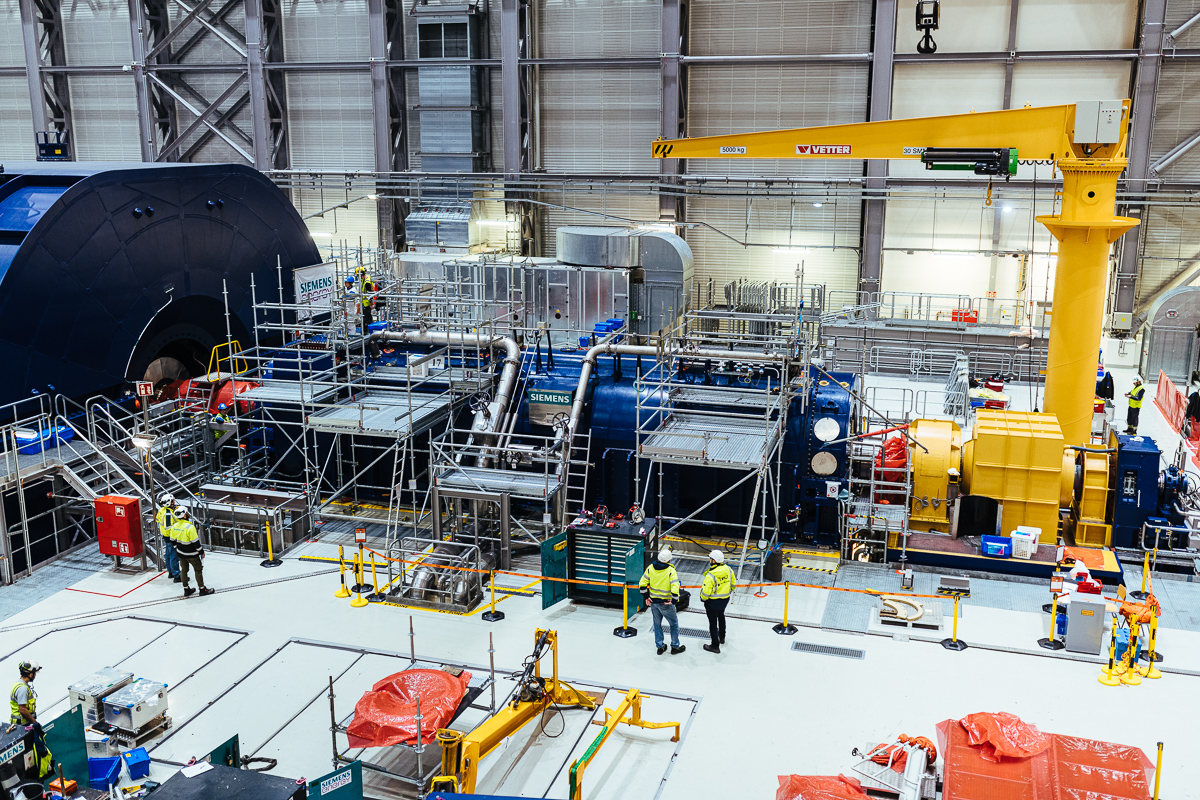

In practice, most of the team consisted of personnel from Siemens, the supplier. Some of the people had already spent time at Olkiluoto during the test operation stage. The official language of the worksite was English, with German being a close second.

A special first time

Mr Sundell says that the first annual outage included more inspections than is typical for standard yearly maintenance. The most important of these were the robotic inspections performed on the stator and rotor.

- This allowed us to measure the condition of the generator quite precisely, he says.

Another slightly more demanding step were the high voltage tests, which provided information on the condition of the isolations, for example.

- These are both actions that were now included in the first annual outage but that will need to be repeated every 4–5 years going forward, Mr Sundell says.

Many of the inspections performed now will be repeated each year, however. According to Mr Sundell, these include inspections on shaft seals, bearings and auxiliary systems, among others.

Continuous improvement in practice

Mr Sundell is happy with how all the maintenance work that had been planned for the generator was completed on schedule. The inspections did not reveal any surprises, either.

- Actually, the only additional work we did was related to an observation made during the leak rate test that followed the maintenance, and even that did not take us more than a day, he says.

As regards OL3’s generator, the annual outage now been successfully completed; in practical terms, however, planning for the next year has already started, as there are approximately 11 months to go until the following outage.

- Preliminary planning is started more or less immediately, as the findings and needs for change are now fresh on our minds, Mr Sundell notes.

At the same time, spare parts are sent out to be serviced, and we will also be examining the spare parts requirements for the next annual outage.

- We will also review the performance of the maintenance with the plant supplier and think about ways to further improve our collaboration, he summarises.

The maintenance team from Siemens consisted of approximately 30 people, including technicians, supervisors, inspectors from various competence areas and experts who analyse the findings made during the inspections. Many of them had already been at Olkiluoto during the test operation stage.

Even after five years, there are still new things to learn

In April, Taneli Sundell will celebrate five years of full-time employment at TVO. However, he was already familiar with the island before this.

- I completed nearly all of my summer internships here back in the day and even wrote my thesis on maintenance at OL3, he explains.

In his work, Sundell especially values his interesting and versatile area of responsibility.

- There is so much to learn here that I will spend many more years taking it all in, he says, smiling.

Text: Ville Kulmala

Photos: Tapani Karjanlahti

Share