Olkiluoto leads the way in utilisation of 3D technology in nuclear industry

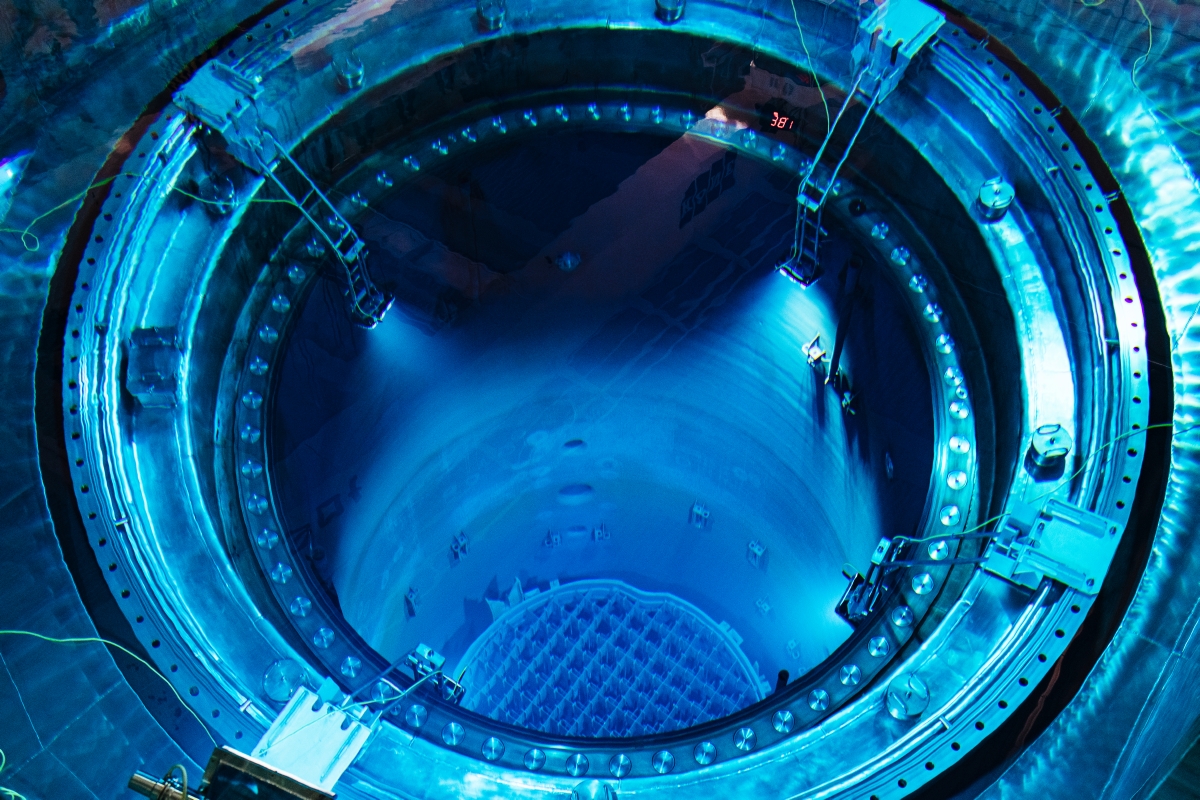

In the refuelling outage carried out at the Olkiluoto 2 unit (OL2), two fuel assemblies equipped with 3D printed filters for exclusion of foreign material were loaded in the reactor.

In the refuelling outage carried out at the Olkiluoto 2 unit (OL2), two fuel assemblies equipped with 3D printed filters for exclusion of foreign material were loaded in the reactor.

These are the first 3D printed fuel components with regulatory approval for use at a nuclear power plant. The StrongHold AM filters were manufactured by Westinghouse Electric Sweden AB using the 3D print technology.

– We can boast playing a pioneering role, even globally, in the utilisation of this new technology at nuclear power plants, says Fuel Procurement Team Leader Arttu Knuutila from TVO.

With 3D printing, it is possible to include in the foreign material filters structures that could not be produced with conventional manufacturing methods. The construction of the filters provides improved protection against the entry of foreign material in the fuel assemblies. The foreign material filters of the fuel assemblies are designed to prevent fuel damage by stopping any foreign material from entering the fuel assemblies.

– As the first 3D-printed fuel debris filter for insertion in a nuclear power plant, the StrongHold AM marks a major milestone in our effort to further improve the BWR fuel reliability by leveraging advances in manufacturing technology,” says Dr. Carina Önneby, Westinghouse VP EMEA Fuel Delivery.

The 3D technology can be used to produce at competitive prices also products that are difficult or even impossible to find on the market.

TVO's own research and development function is strongly involved in the design and production of 3D prints. The 3D printed foreign material filters developed in a collaboration project of Westinghouse Electric Sweden AB and OKG AB are a concrete example of successful cooperation.

– We can now gain important practical experience in the use of 3D printed metal products which will become an ever more important operational solution going forward. It is important to have a strong network of partners like Westinghouse who deploy additive manufacturing to drive enhanced capability, Mr. Knuutila stresses.

*BWR=Boiling Water Reactor

Share