Unique analysis capabilities

The analysis program package used by TVO is the result of a long-term development process. The Piping and component Analysis and Monitoring System (PAMS) contains several databases and independent software modules utilised to ensure the safe operation of the Olkiluoto plant units. Analyses related to loads, stresses and inspections of the plant units are carried out with the system.

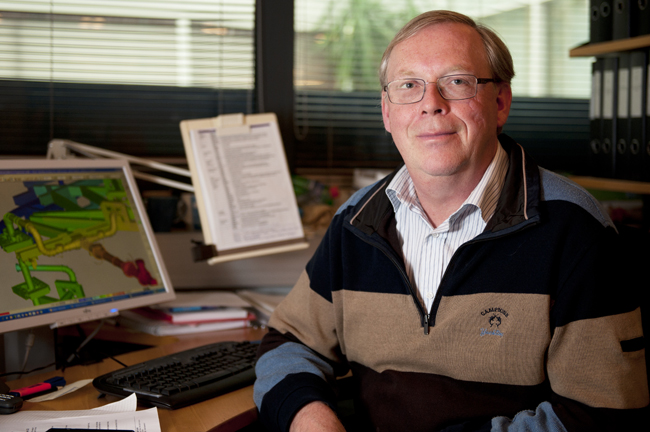

– This program package developed at TVO and the utilisation of data in this way is something that is unique in the world, as far as I know, states TVO’s Stress Design Manager Paul Smeekes.

Increased analysis efficiency

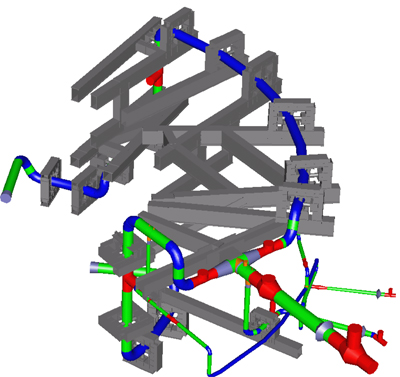

PAMS can be used to illustrate e.g. piping at the existing plant units. A visual view is created on the display screen of the pipe junction points, so-called node points, as well as of pipe sizes, support structures, welded joints and stresses.

– We have mainly focused on piping systems inside the reactor containment as they are relevant to nuclear safety. However, data have over time also been recorded on pipe support structures as well as on systems outside the containment.

With the help of the data documented in the loading database, specific piping sections can be analysed by adding certain load factors to it, such as pressure or temperature, or even additional loads caused by an earthquake.

– Fatigue analyses and stress analyses for pipe systems are routine work. Such analyses are important in cases where special attention needs to be paid to the effects of pipe content and ambient conditions when planning modifications at the plant units and estimating their lifespan.

The programs are linked to a database, which contains the analysis results. A special read-back program makes it possible to read the results back to the system so that they can be used by the software as a whole. The results are then available for further analyses and for new documentation.

The software has connections to other analysis programs and the basic data contained in the database can be automatically entered in these programs. – This increases the efficiency of our analyses, since both the basic data and the analysis results can be quickly transferred for further utilisation.

Continuous software development

The development of PAMS started in 1995, when Mr. Smeekes was searching documents and reports to be used as input data for analyses.

– It was a challenge to find the data quickly from the rows and rows of folders, and a better system had to be developed for searching data. This was the starting point in the development of the program and a common document database. Now there are different databases that contain several hundreds of thousands of lines of updated information, such a structural and material data, links, descriptions, calculations and comments, Mr. Smeekes concludes.

The system is used on a daily basis. A team of seven persons works with the analyses of Olkiluoto 1 and 2. The system has also to some extent been used in the comparison analyses of Olkiluoto 3.

The development of the software continues. – We have ordered a thesis on the improvement of the reporting tool. It is important that students interested in analyses get the opportunity to develop this software system, Smeeks states with satisfaction.

PAMS is excellently suited for piping demonstrations. The illustration shows the feedwater piping and its support structures.

Share