Refueling is an important part of the annual outage

The annual outage of TVO's nuclear power plant in Olkiluoto is well under way. The refueling outage of Olkiluoto 1 started on Sunday, 3 May, and the plant unit was reconnected to the national grid on Thursday, 14 May. On Sunday, 17 May, Olkiluoto 2 underwent a longer service outage, which is expected to take about 15 days. As always, the outages of both plant units have many things in common: accurate advance planning, scheduling and resource allocation, and refueling.

The reactors are operated in a one-year cycle. For each cycle, less than a quarter, i.e. 100–110 of the 500 fuel assemblies in the reactor are replaced during the annual outages. The amount of fuel replaced is determined by its excess reactivity, which corresponds to the energy to be generated during the cycle.

The reactors are operated in a one-year cycle. For each cycle, less than a quarter, i.e. 100–110 of the 500 fuel assemblies in the reactor are replaced during the annual outages. The amount of fuel replaced is determined by its excess reactivity, which corresponds to the energy to be generated during the cycle.

The reactor cover was opened on 4 May

This is the second time that Jani Malila from fuel and waste treatment operations is working on the refueling during his now four-year career in TVO. His outage work started on Monday, 4 May with opening of the OL1 reactor cover. Last year he was not involved in the opening of the cover, so this task was new to him.

- Opening of the cover in full protective clothing is hard work. First, we had to wait for the reactor temperature to drop below 60 degree Celsius, Jani says.

The actual work took three hours. Together with Jani, two other TVO workers and three subcontractors participated in the work.

Underwater activities

Underwater activities

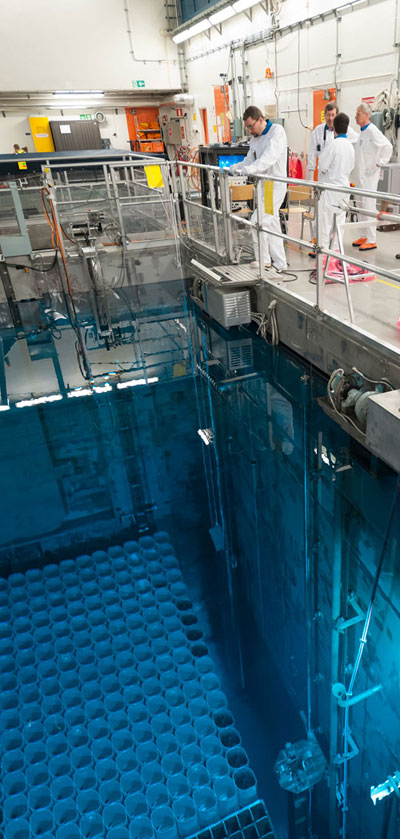

After removal from the reactor, spent fuel assemblies are transferred by means of a refueling machine and underwater camera to the fuel pools located in the reactor hall. The assemblies must be completely under water throughout the operation, which makes the work challenging.

The fuel assemblies are cooled down in the fuel pools for about five years. The water cools down the fuel and protects the environment against radiation. After cooling down, the assemblies are placed in a sturdy, water-filled transport cask, which is transported in a specially designed vehicle to the on-site interim storage facility for spent fuel. The transport cask accommodates a maximum of 41 fuel assemblies, and it weighs about a hundred tons fully loaded.

The placement of fuel assemblies into the reactor needs precision

Fresh fuel emits very little radiation. According to Jani, fresh fuel assemblies can be handled with cotton gloves. The new fuel assemblies are transferred into the storage pool around the turn of the year. In the outage, they are then placed into the reactor in a carefully planned order. At the same time, also the functionality of the control rods is inspected and worn rods are replaced.

- In this work, it is very important to have very good lighting, excellent underwater camera and other equipment, and good eyesight, Jani says and continues that he and his colleagues should take an eye examination every year.

Controlling the refueling machine also requires skill and precision and special training.

Apart from refueling, during the outages Jani is also involved, among other things, in control rod inspections, final inspection of the reactor core, and closing of the reactor cover after the outage works. These works are carried out in three shifts, including weekends.

Share