Subcontractors' accident figures reduced through safety assessments

The employees of both the Client and the subcontractor must be aware of practices that help achieve the common goals. The game rules must never be forgotten, regardless of the degree of urgency. The objective of a safety assessment is to increase the safety level of the workplace, reduce the number of accidents and incidents, and promote the zero-accident philosophy.

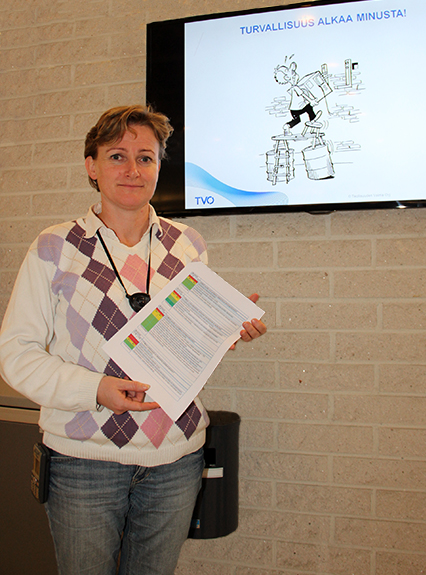

TVO has organised training events in the safety assessment process of external subcontractor companies, developed by the Finnish Centre for Occupational Safety. But is not as if subcontractors have not been assessed before, why has this new assessment method now been introduced, TVO's Occupational Safety Manager Sarianna Niemi?

– Early in 2014, our attention was drawn to the risen work accident figures of our smaller subcontractors. We wanted to react to them without delay, and establish the causes of the accidents together with the subcontractors. We also decided to assess the adequacy of our own quality control process in the same context. The safety assessment of external operators provided a tool that was just right for this purpose.

Assessment forms and discussion

In the assessment process, attention is particularly paid to the basic matters, which should already be in order in every company. – Smaller companies, however, do not always have enough people with special knowledge about occupational safety. And maybe their safety culture is also still evolving. In any case, there are certain principles that need to be followed in Olkiluoto. The purpose of the assessment that has now been started is to verify even further that our subcontractors understand the safety significance of matters from several different viewpoints.

The safety assessment is based on a dialogue between the Client and the supplier. The supplier is required to fill out in advance a form that contains questions about safety-oriented leadership, management of safety and development of safety competence. These subject areas cover a large number of matters that are then discussed on the basis of the form.

– Based on the results, a development plan is prepared for the subcontractor, together with the subcontractor. The execution of the plan is monitored by means of assessment discussions. These discussions are, as a rule, conducted in the facilities of the subcontractor to give us an opportunity to also check their work environment. That can also tell surprisingly much about the status of the company, Ms. Niemi says.

Benefits all parties

The significance of the safety assessment is increasing all the time. – We want everybody to be ok when they go home after their work day at TVO and not have sustained any injuries. Because of that, we are willing to help the subcontractor companies to develop their own occupational safety procedures. The intention is not, however, that TVO implements the development work for the subcontractor; every company must actively invest efforts in rectifying any shortcomings.

We are not talking about an audit, but an improvement of the safety level, implemented together. – Efficient and reliable local subcontractor network is important to us. That is why we find development efforts in the field of occupational safety beneficial to both parties. Increased and joint knowledge always boosts operation.

Sarianna Niemi holding the form filled out in the assessment. The colours indicate the status of the assessed item.

Share