Reactor supervision is precision work

At the existing plant units in Olkiluoto, both reactors contain 500 fuel assemblies. In addition to them, the reactors in which water is boiled to rotate the turbine and to produce electricity feature control rods used to control reactor power as well as several measuring instruments for the supervision of the reactor.

During the life cycle of the fuel, various event sequences that are closely monitored take place in the reactor. Supervision activities are carried out both by the control room operators and the specific Reactor Supervision Team headed by Tiina Kettunen.

Ms. Kettunen, who is a specialist in atoms and their behaviour, describes the tasks of her team as ensuring that the reactor is operated in compliance with rules and safety limit values. By far the most important objective is to maintain the integrity of fuel.

– We work in close cooperation with the operating organisation, as we provide instructions to the control room staff for reactor operation. For example, we plan the manoeuvring sequences of the control rods in the reactor when power changes are needed for e.g. periodical tests. During the annual outages, we also prepare work instructions related to fuel transfers.

The operation of the reactor is monitored from the control room on a 24/7 basis. In addition to the automatic systems, the Reactor Operator and the Shift Supervisor monitor several different graph displays. If necessary, the operators will contact the Reactor Supervision Team even at night time.

– The first thing I do every morning when I come to work is check the status of the reactor. The parameters we monitor include reactor power, recirculation flow, safety margins and fuel stresses. We have two parallel reactor core supervision systems in place for this purpose, Ms. Kettunen explains.

Reactor fuel transfers based on an exact plan

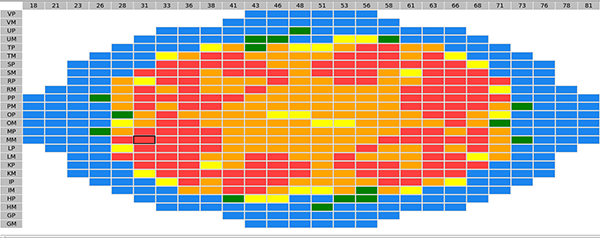

During annual outages, about one fifth of the fuel is replaced. The reactor analysis division produces in good time before the outage a refuelling plan for the new fuel assemblies using a modelling program. The different core patterns that determine the locations of the fuel assemblies must be exactly correct.

– The location of each fuel assembly is optimised in the core patterns. The new and the old assemblies are located in a suitable relationship with respect to each other to ensure the best possible end result in terms of both safety and fuel economy. The Radiation and Nuclear Safety Authority is also a close cooperation partner to us, because the reactor cover cannot be closed until the authority has approved the core pattern.

According to Ms. Kettunen, the planning of the use of fuel is of an excellent standard at TVO, which is reflected in the flawless operation of the reactors.

– The foundation is laid years before through long-term planning of the use of fuel. The operation of the reactor is directly influenced by both good and bad planning work, Ms. Kettunen sums up. The core pattern determines the location of each fuel assembly exactly.

Share